Creating a superior battery to propel EV into a primary mode of road transportation has been a goal for countless start-ups and established companies over the past decade. And while the majority of companies focus their innovation on building more durable batteries that can take their customers’ electric vehicles on longer trips without having to stop at a nearby charging station, one organization has been concentrating its efforts on drastically reducing the battery charging time to improve convenience and customer satisfaction: introducing StoreDot, an Israeli-based developer of innovative lithium-ion batteries.

In their enthusiastic promotional video and collaboration with British Petrol, StoreDot claims that they have managed to develop technology to charge a lithium-ion battery in under 5 minutes fully and can endure up to 300 miles on the road, depending on the EV model. Recently, StoreDot gave The Guardian an exclusive to share more information about this approach to battery design. We have done our own research and gathered information to bring you details about this technology’s current progress.

A Different Approach

The one key characteristic that separates StoreDot from other companies in the EV lithium-ion battery business focuses on faster charging times. Although they are still very much committed to the range (as stated before, their batteries can theoretically endure up to 300 miles of driving), the main selling point is enabling super-fast charging to overcome “range anxiety” of having to wait forever at a charging station in a middle of nowhere while taking a road trip. To put it in simple terms, they are betting customers would rather drive cars that can go 300 miles and recharge in 5 minutes instead of going for 600-800 miles and having to wait an hour to recharge.

What are the potential consequences of utilizing this approach? The main one is overheating the battery, of course. Faster battery charging naturally produces more heat, which can prove destructive for the battery itself. The way StoreDot is trying to resolve this problem is by designing the battery with plenty of space between cells as well as holes in battery housing and charging it in a stand with multiple fans, all to create enough airflow space for the battery to sufficiently cool while being charged.

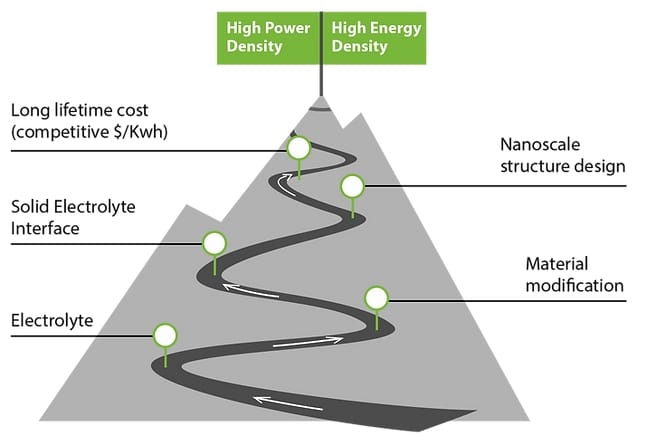

Designing a battery to enable more airflow for better cooling, however, seems straightforward enough. So why did nobody else think to utilize this approach? The problem with this design is that the battery itself would have a significantly lower energy density, which translates into drastically increasing the size to hold the same amount of charge as a traditional EV lithium-ion battery. StoreDot is handling this problem by creating a technology that enables a higher charge density, allowing their battery to hold similar amounts of charge per volume as its current competitors.

Chemistry Behind It All

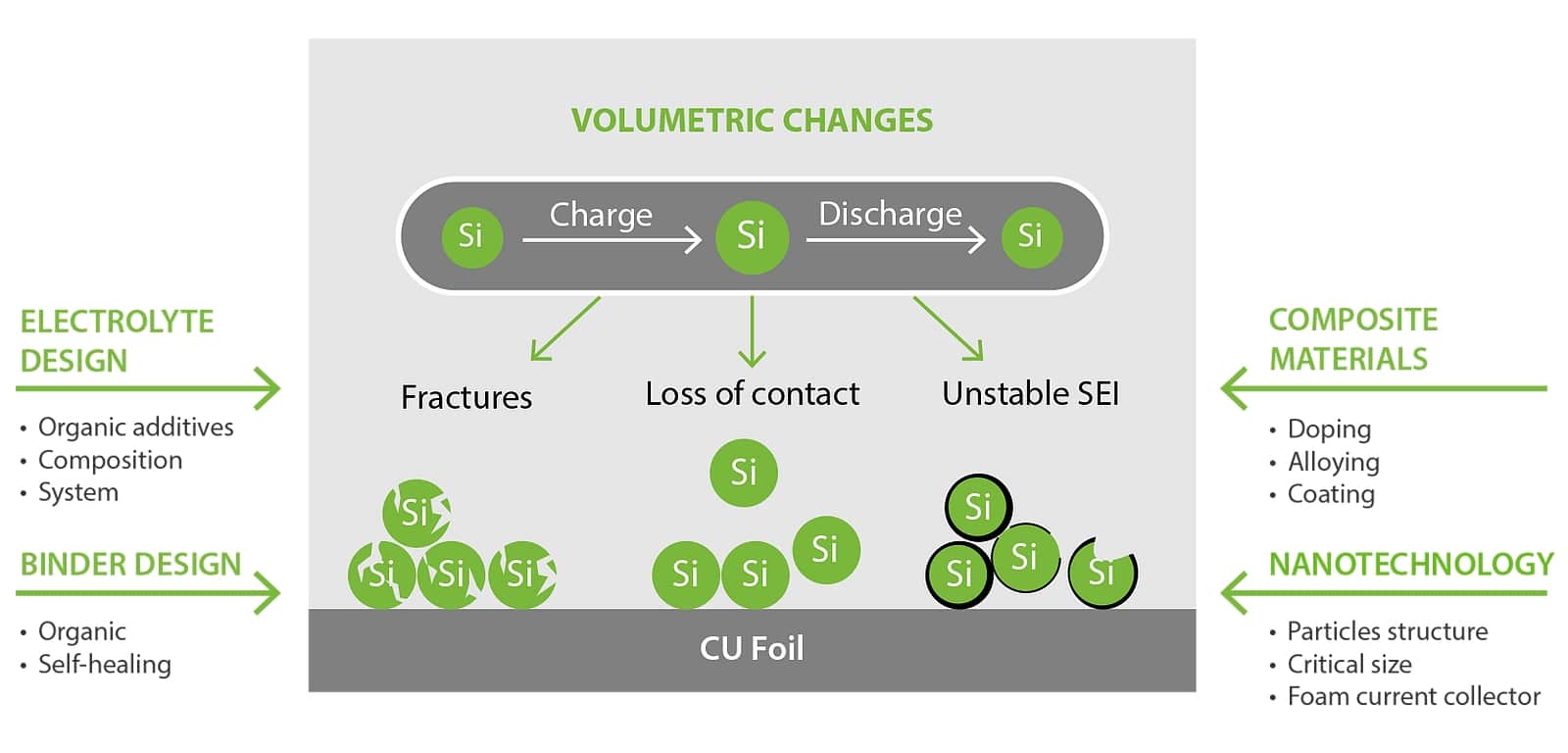

What is the actual problem behind this technology on a smaller scale? The nature of lithium-ion batteries is such that they need to have electrodes made of certain materials to store the lithium ions when they do not carry charges between electrodes. Today’s most common material is graphite, which is basically composed of many layers of graphene sheets, where the ions can be tucked in. Other options in place of graphite are sulfur and silicon, which can store more lithium per unit. However, they are not without their problems; sulfur tends to have undesirable chemical reactions inside a battery, and silicon, although not reactive, can drastically expand when stored with lithium, leading to structural damages to the battery. However, StoreDot is trying to resolve issues with silicon and use it as a primary storage material.

Solutions that the company is implementing to address the silicon-expanding issue tackles both large-scale and small-scale problems. The large-scale expansion problem (the one that deals with the battery’s structural integrity) is dealt with through previously mentioned innovative design, where cells are spaced apart. There is plenty of space for airflow to deal with overheating issues. The small-scale issues are resolved by turning silicon into nanoparticles, making it more conducive to a bonus. Furthermore, they use a flexible polymer that can self-heal if breaking occurs due to silicon expansion, as indicated by the company. StoreDot has not indicated whether this polymer is also conductive or if there is maybe another conductive material in the design which has to expand along with the silicon during the process.

Unresolved Issues

In an interview with The Guardian, the company has indicated that they have already managed to manufacture the product prototype on a mass scale through a Chinese manufacturer called Eve Energy. This partnership will allow StoreDot to produce enough batteries for the market once all issues have been resolved, and there is enough demand for the product. However, the prototypes manufactured do not have the same chemical composition as the final product. Instead of silicon, the company uses germanium, which interacts with lithium in the same way and is much easier to work with. The catch here is that germanium is much more expensive than silicon, which renders it useless for mass production. Due to the company’s limited information, it cannot be determined how challenging it will be to substitute germanium with silicon at this point.

Current State of Affairs and Comparison

There seems to be plenty of progress to be made until this technology can be commercially viable. However, with what we managed to find out so far, this revolutionary tactic to enhanced customer satisfaction seems to be showing some promising results. The presence of a mass-produced prototype is certainly encouraging, but plenty of mysteries remain. This is because StoreDot uses the development in materials science to propel its EV battery technology, and those developments are commonly unavailable to the public eye due to proprietary information that goes along with it. Nevertheless, this unique approach to developing EV lithium-ion batteries might be exactly what ends up being the breakthrough we have all been waiting for the decade.